This category includes toothed mechanical components designed for power transmission or for use with timing belts in synchronous transport systems. To ensure the highest standards of quality, all our pulleys are manufactured exclusively in Italy using certified materials. These components are widely used across various industries, including automatic machinery, packaging, industrial automation, machine tools, woodworking, glass processing, paper and textile industries, as well as in the food, pharmaceutical, cosmetic, and beverage sectors.

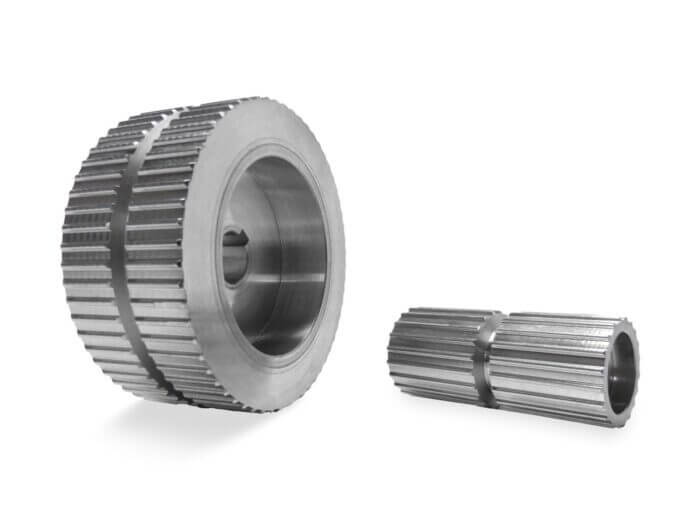

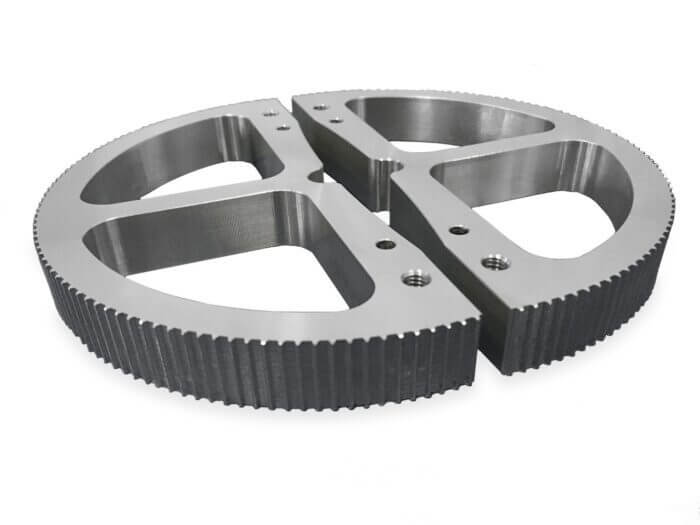

Pulleys for Timing Belts

When designing a transport system based on timing belts, it is essential to produce corresponding pulleys with exceptional precision—something that standard, off-the-shelf components often cannot guarantee. To ensure top-level quality and perfect alignment with the belt teeth, our production process begins with CNC machining centres and lathes to carry out the initial shaping. The final step involves cutting the toothing, using the previously machined surfaces as precise reference points to guarantee optimal alignment and performance.