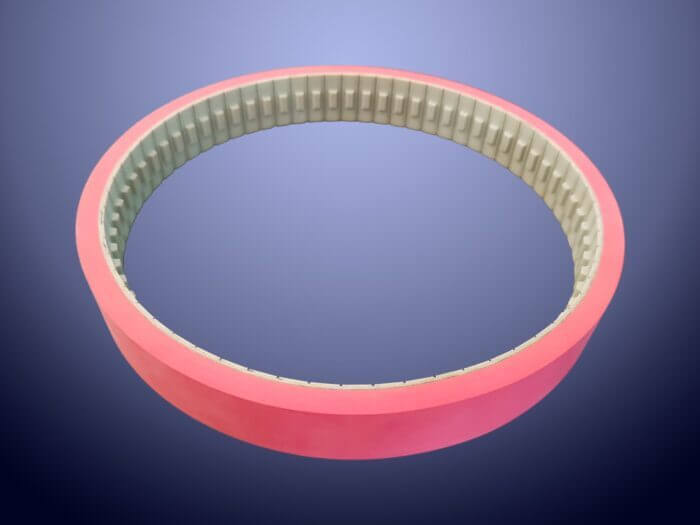

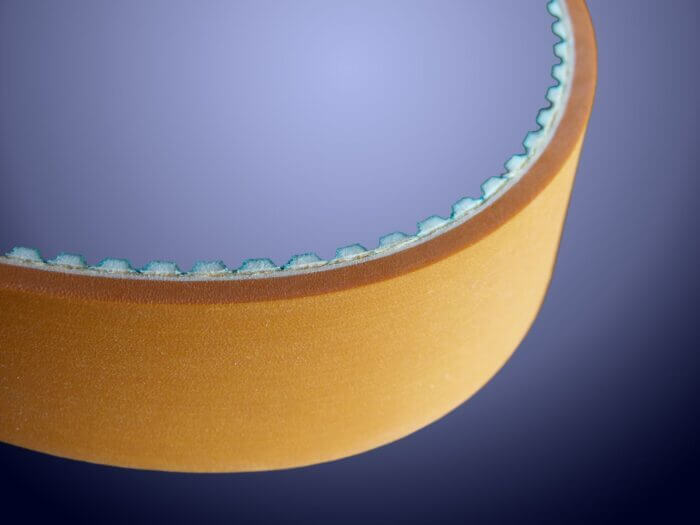

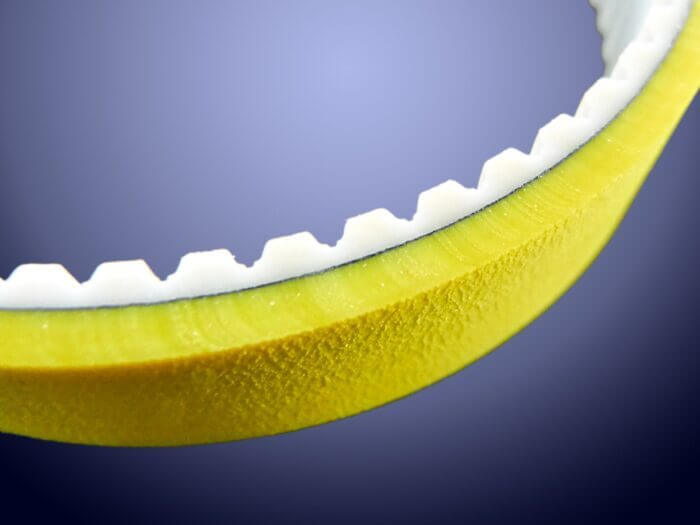

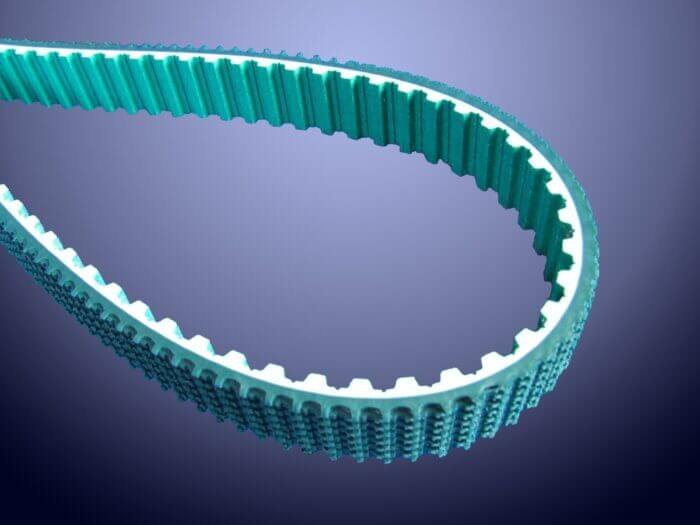

There is a wide variety of coatings that can be applied to the back of timing belts, and based on your specific application needs, we can recommend the most suitable solution, balancing both technical performance and cost-effectiveness.

Coated belts are used across a broad range of industries, including packaging, glass, wood, ceramics, automation, and foodstuffs. Depending on the product being transported, coatings with varying hardnesses and properties are selected to ensure the optimal level of grip is achieved.

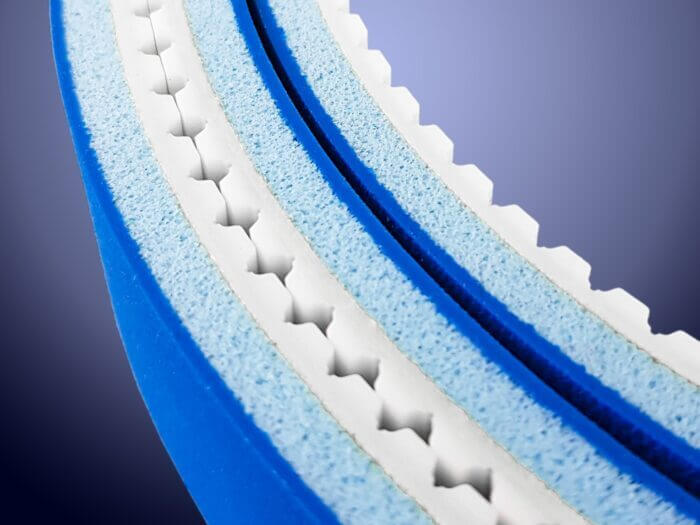

Cold-Glued Coatings

The cold-glued coatings category offers the broadest range of solutions, enabling us to meet the specific needs of each conveyor system effectively. With our expertise, we can ensure the reliable attachment of any type of coating, regardless of the grip requirements or varying hardness levels. This includes materials such as Linatex, Linatrile, food-grade rubber, oil-resistant rubber, and more.