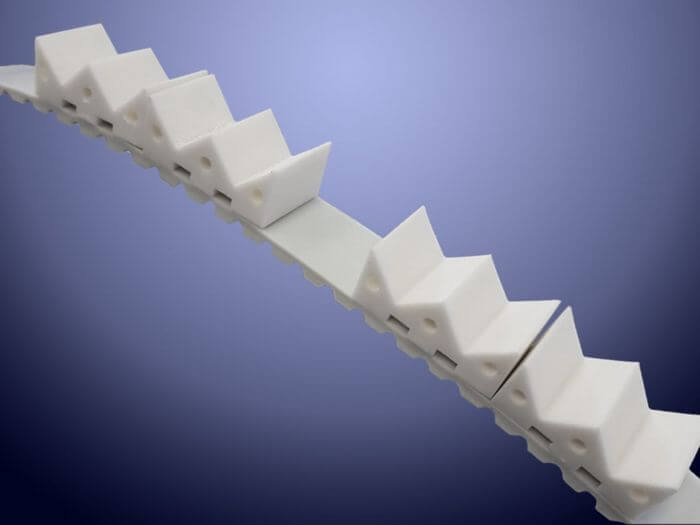

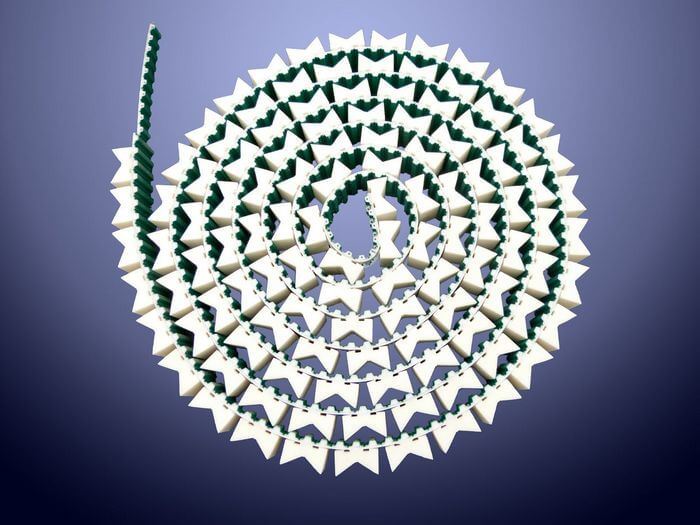

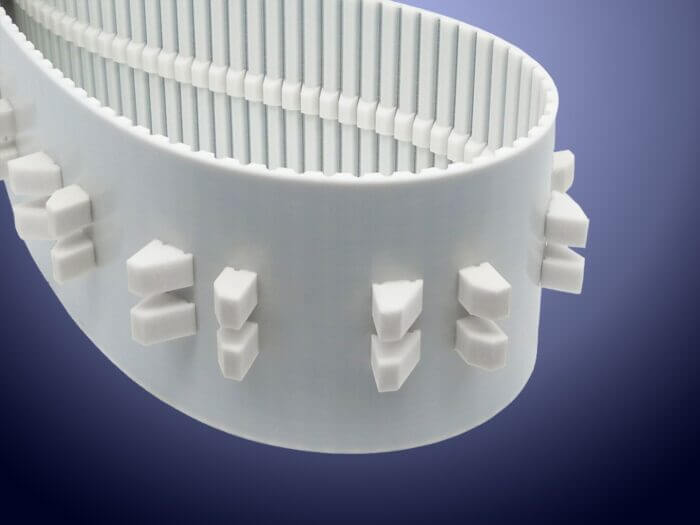

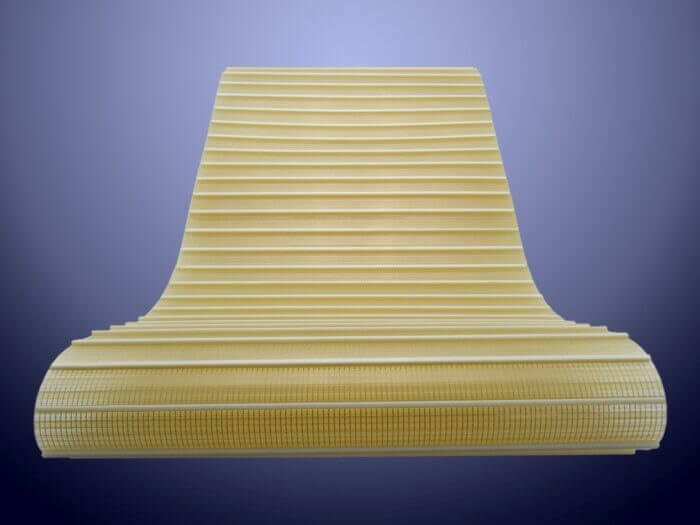

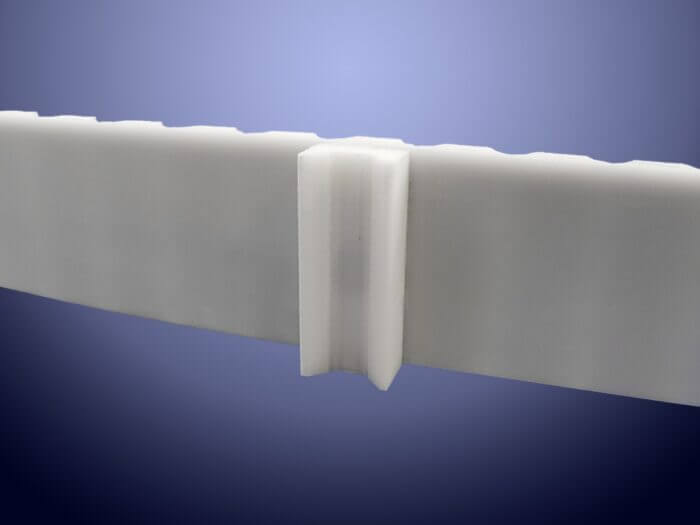

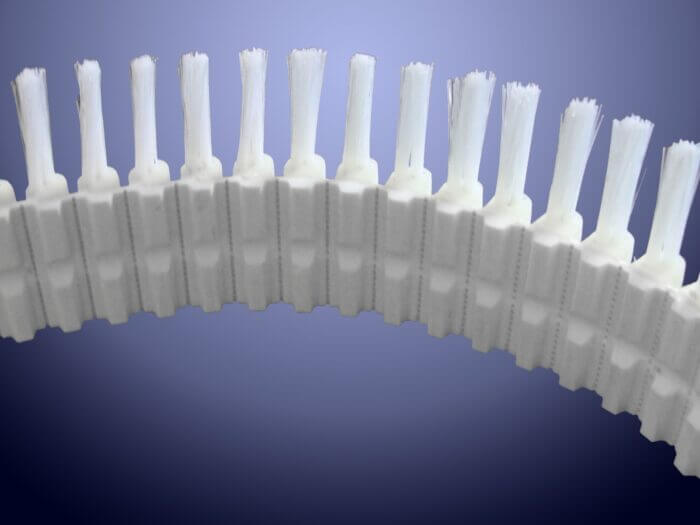

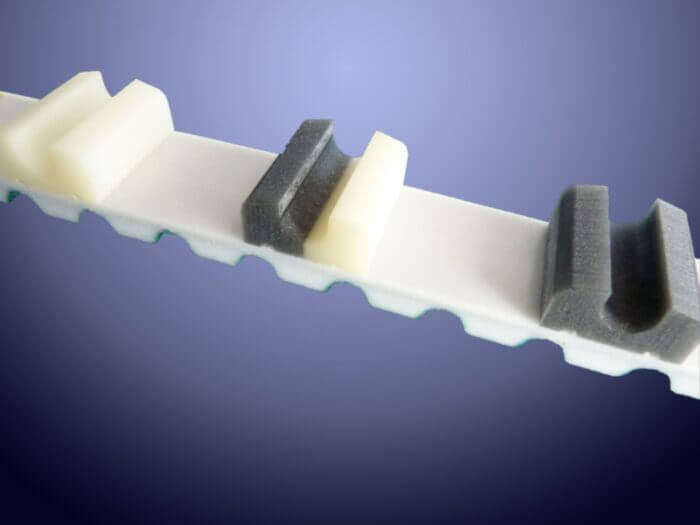

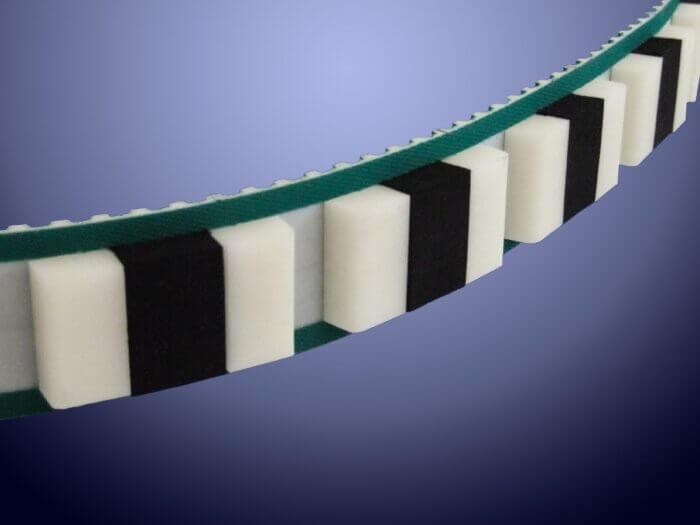

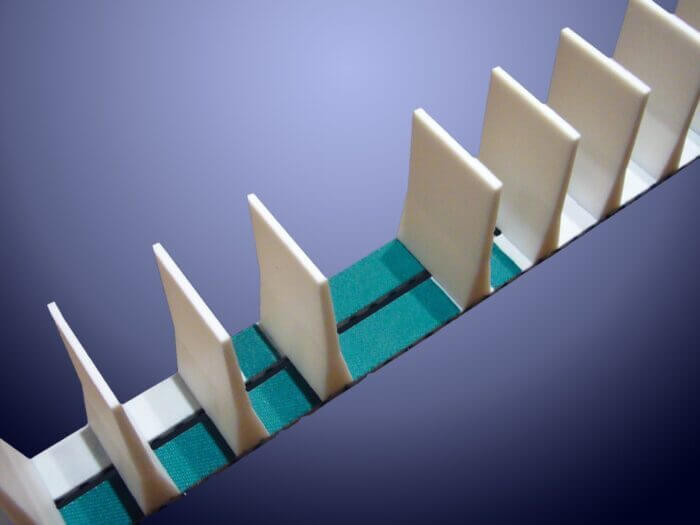

In recent years, the variety of packaging solutions on the market has grown exponentially, bringing with it a rising demand for attachments with highly specific shapes. Thanks to our extensive experience in the field, we are able to supply attachments in virtually any geometry. Timing belts with cleats are employed in high-speed, high-precision conveyor systems, particularly within the sectors of automatic machinery, packaging, and industrial automation.

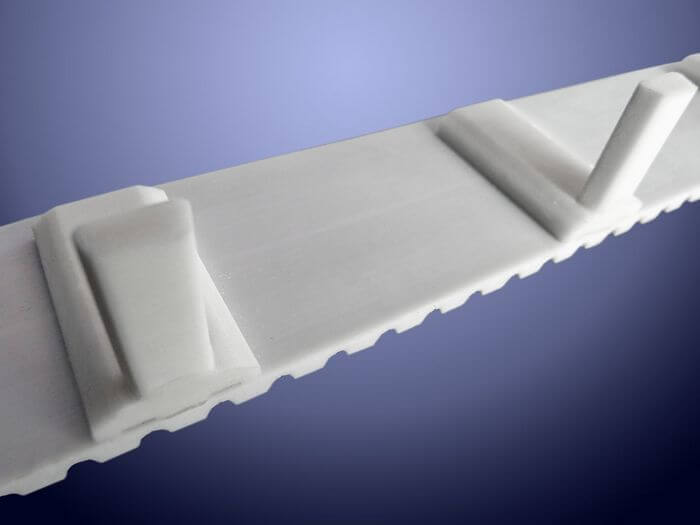

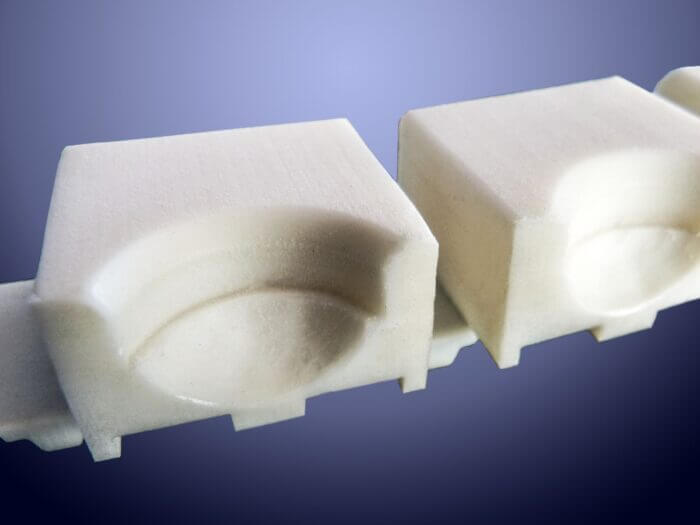

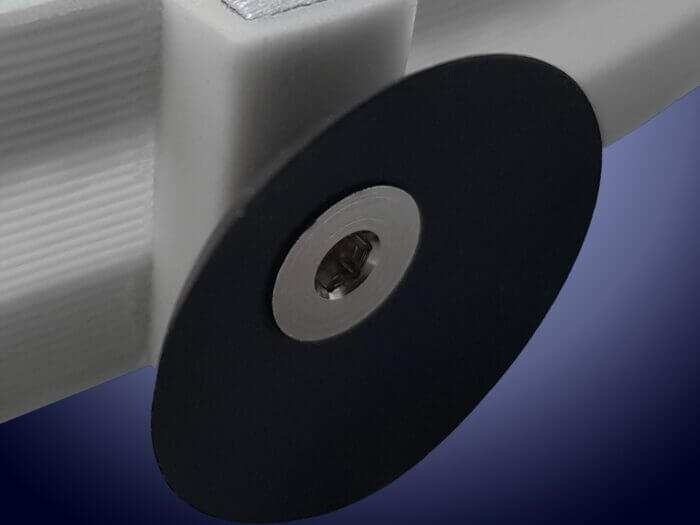

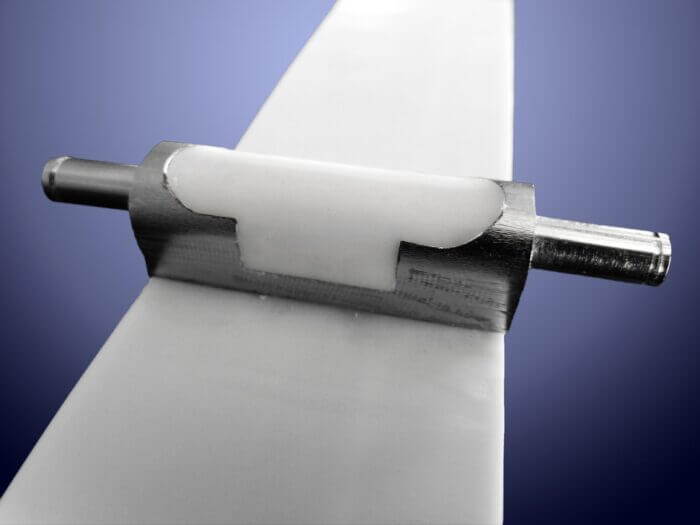

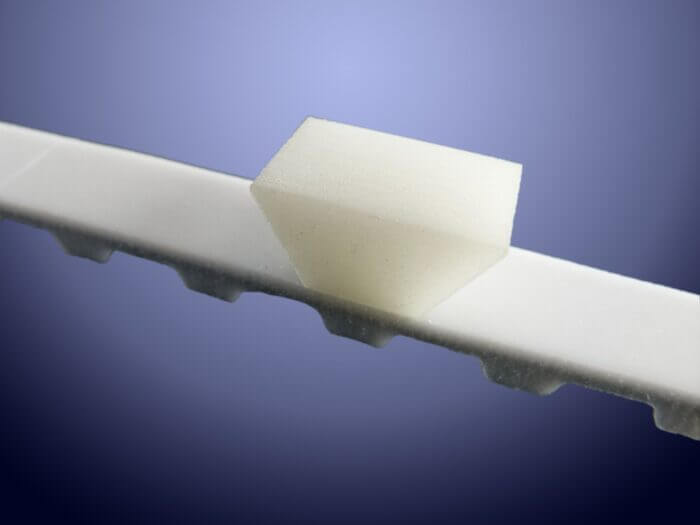

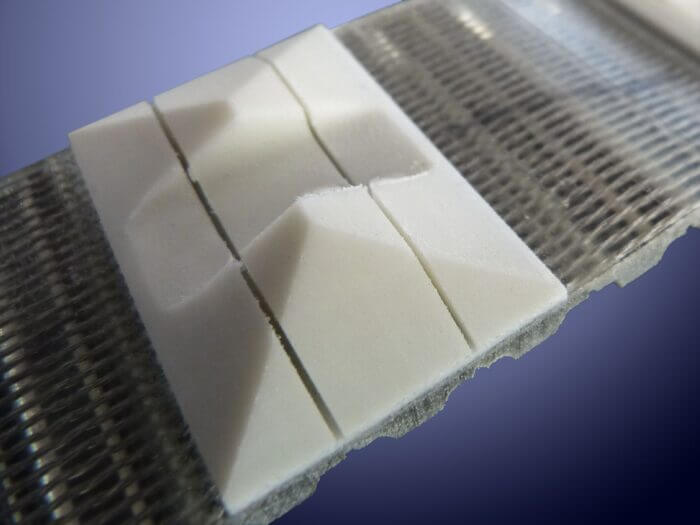

Polyurethane attachments with metal inserts

Thermoplastic polyurethane (TPU) attachments are applied to the timing belt and can be welded onto the back at any position, giving the customer full freedom to choose the spacing of the attachments. Unlike belts with false teeth, the spacing does not need to be a multiple of the belt’s tooth pitch.

Typically, the desired geometries are achieved through mechanical machining. However, in cases where a large quantity of attachments is required, we can produce a mould to optimise manufacturing costs.