In the food, pharmaceutical, and cosmetics industries, conveyor system requirements often call for materials that go beyond those used in standard applications. To better meet these market demands, we have expanded our range of belts that comply with FDA specifications.

In particular, products that are not yet packaged and come into direct contact with the timing belt must be transported using materials certified for food safety. These include specific types of polyurethane, rubber, and silicone that meet FDA standards.

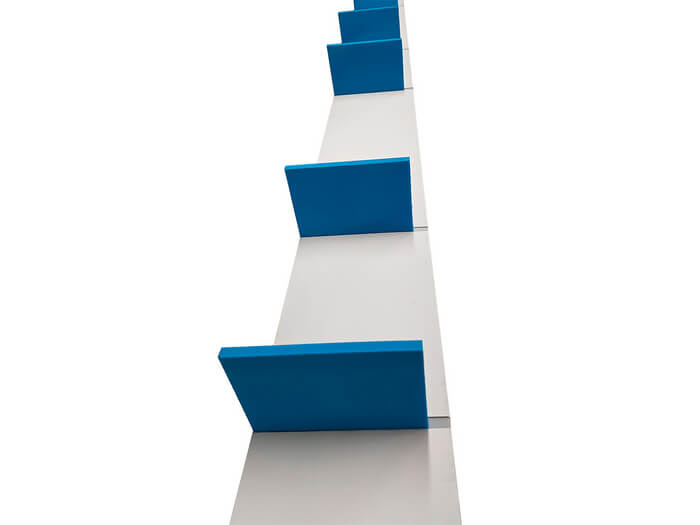

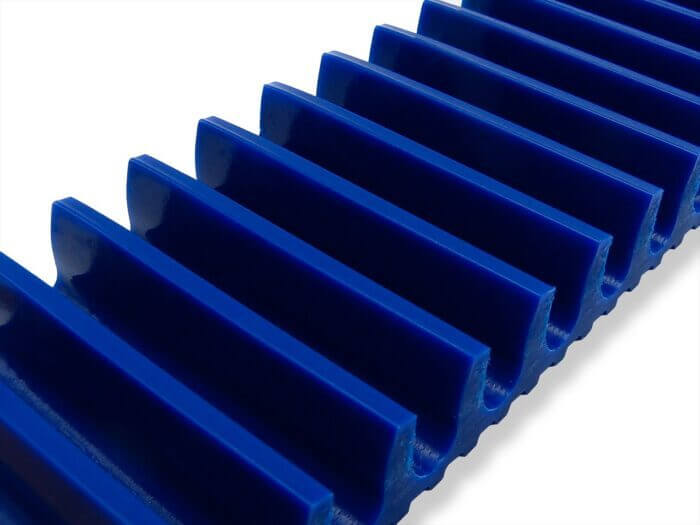

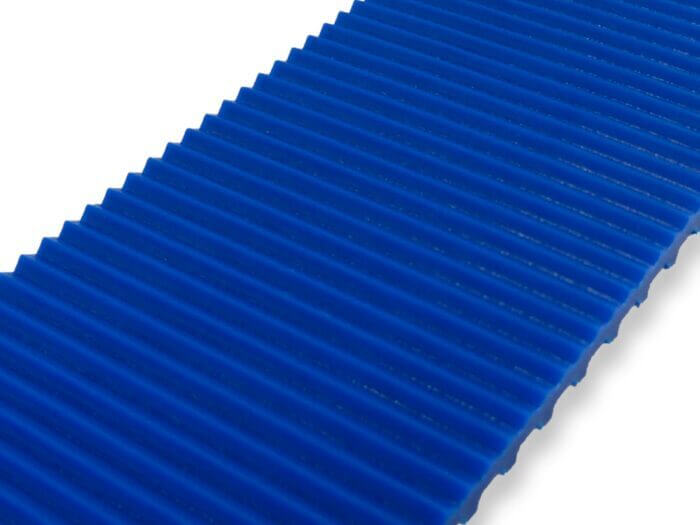

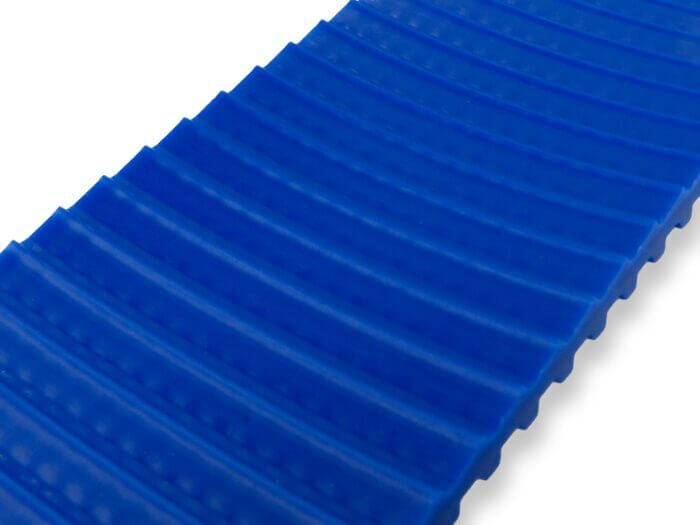

Timing Belts in Food-Grade Polyurethane (FDA)

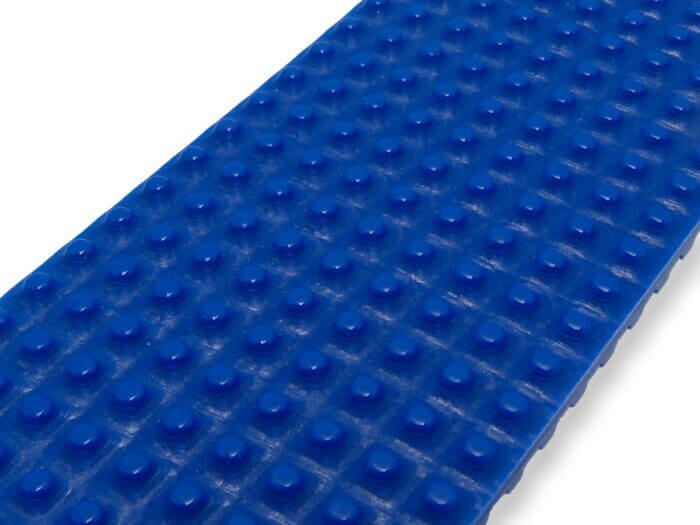

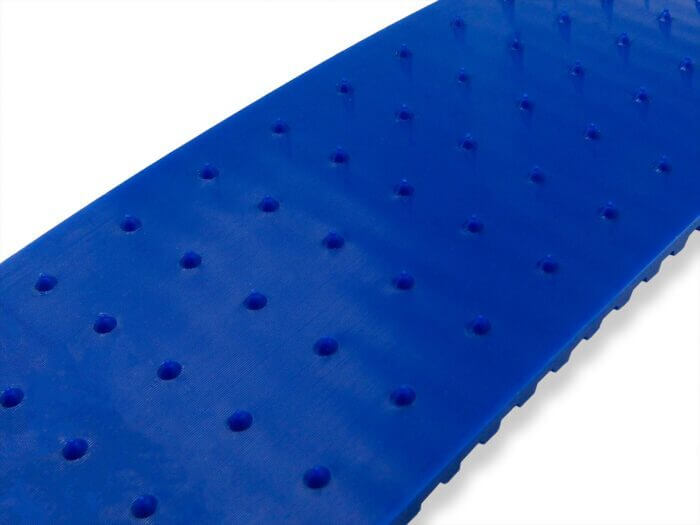

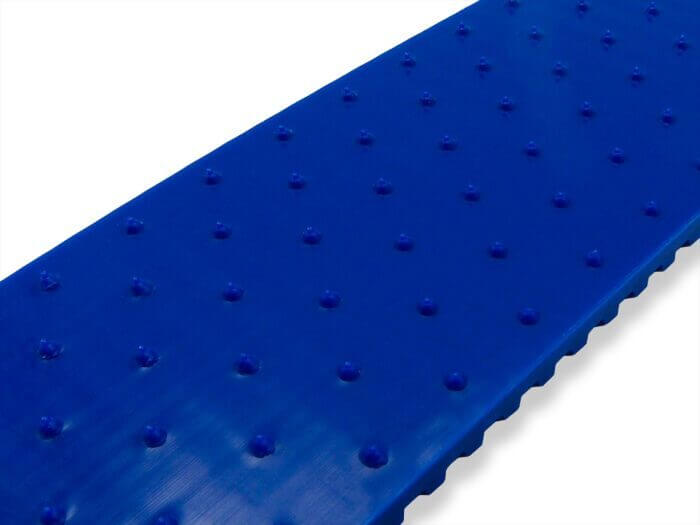

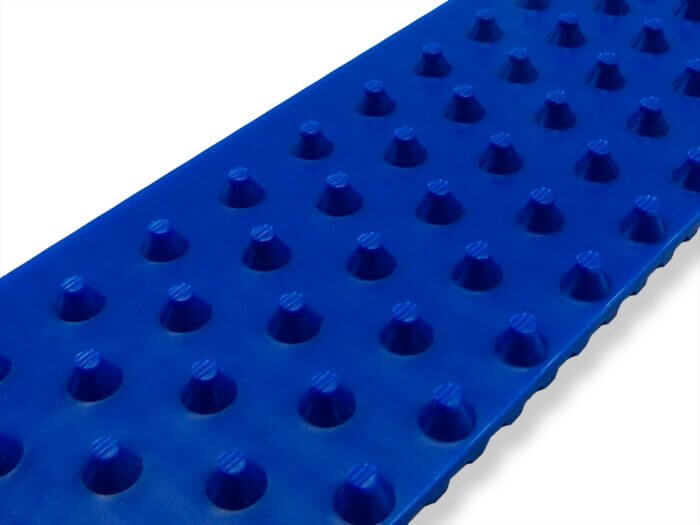

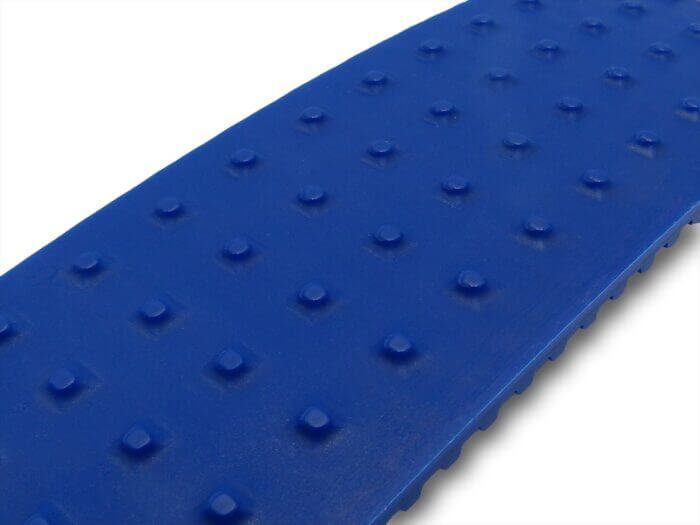

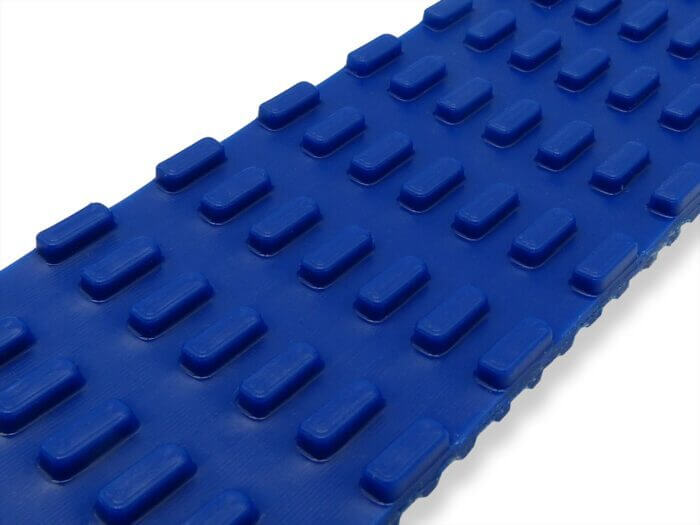

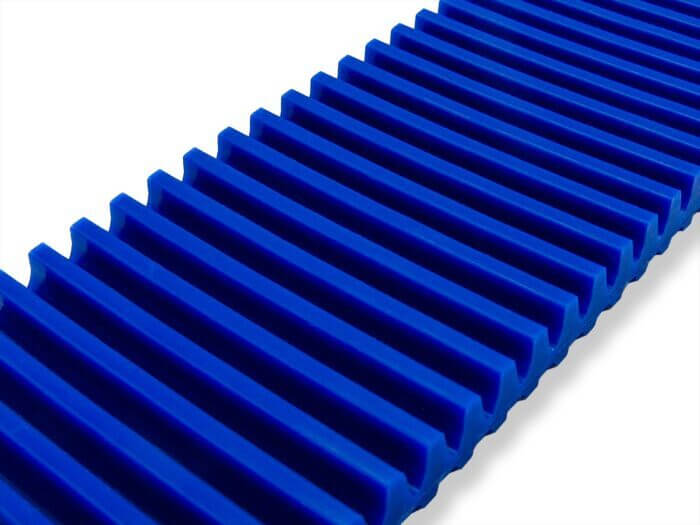

This type of product is distinguished by the use of thermoplastic polyurethane that is FDA certified, typically blue in color, with a hardness ranging from 60 to 90 Shore.

These belts are produced by the meter and can be supplied as endless loops either through welding or with a mechanical joint. The maximum producible width is 300 mm, and available pitches include AT, T, L, XL, and H. The internal tension members are usually made of Kevlar, though in some cases, stainless steel cables can also be provided.