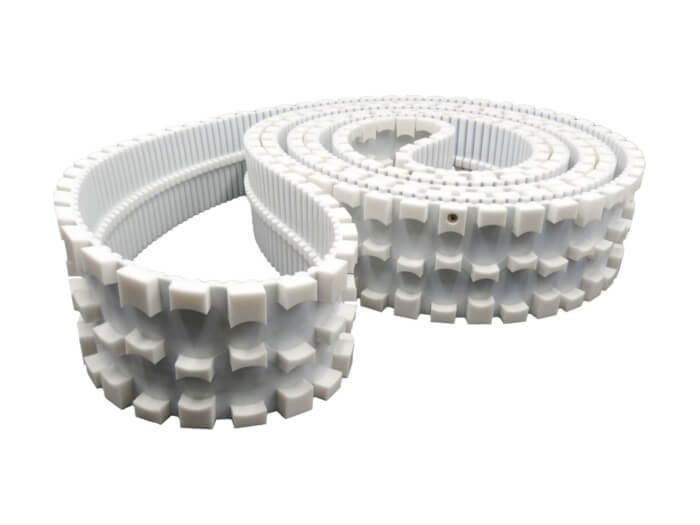

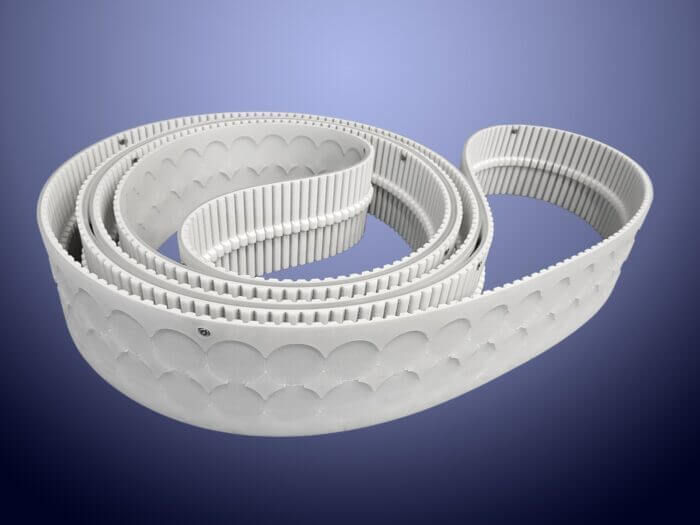

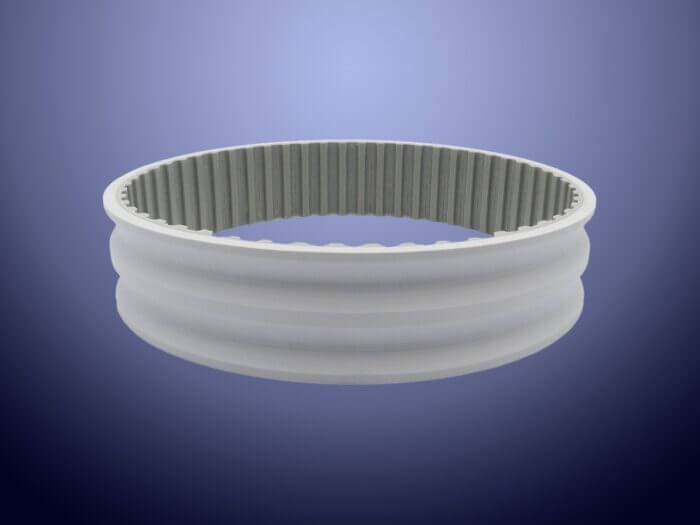

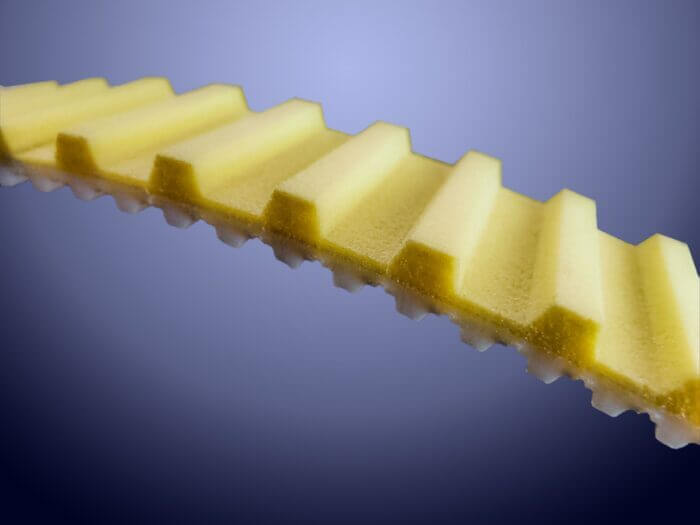

Thanks to our extensive experience, we are able to carry out all types of machining required on timing belts and their respective coatings, whether dense or foam.

Using CAD systems and CNC machinery, we can design and produce custom geometries according to drawing specifications in very short timeframes. To ensure the highest quality standards, we rely on dedicated positioning equipment and, most importantly, custom-designed tooling.

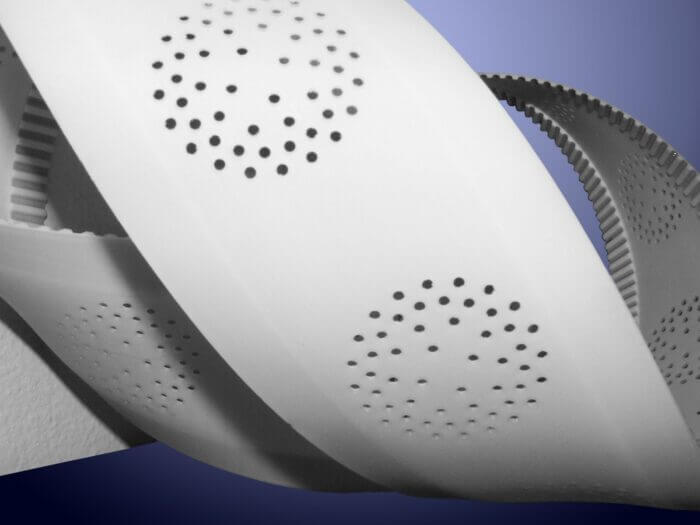

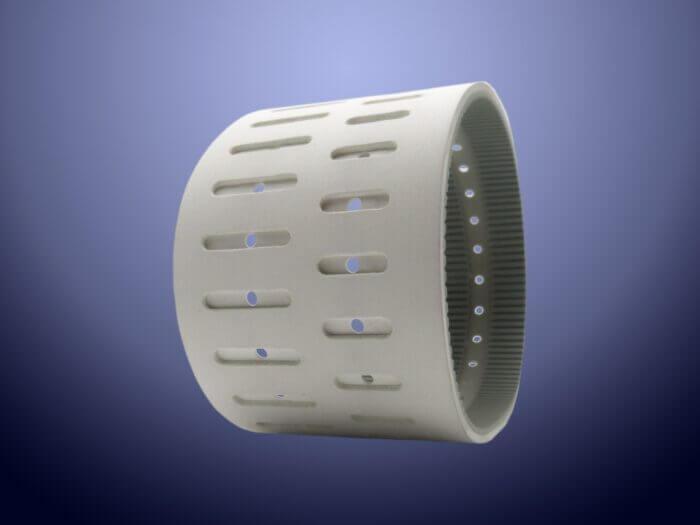

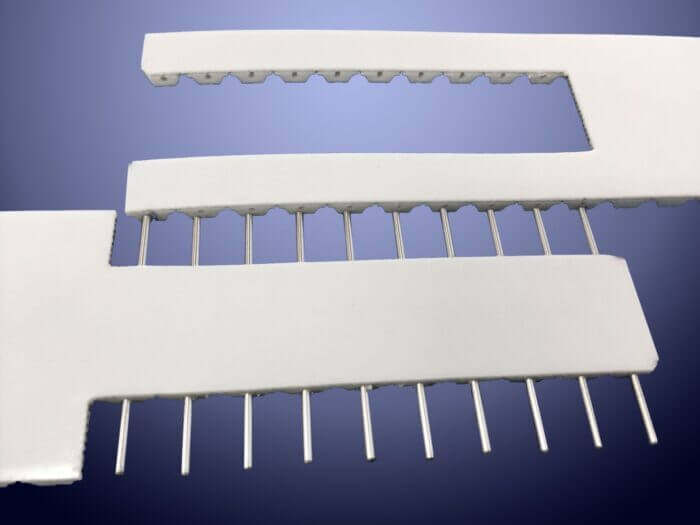

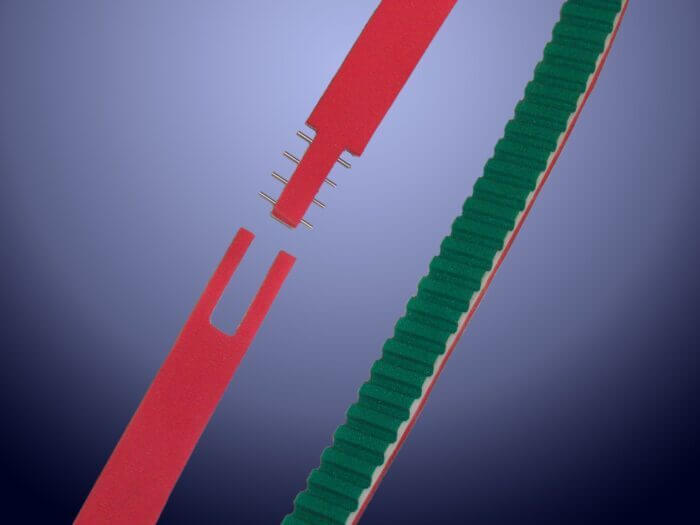

Machining for suction (vacuum) systems

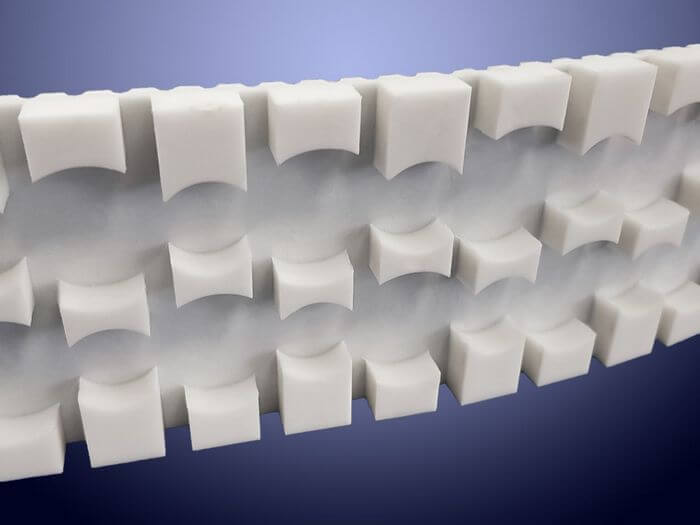

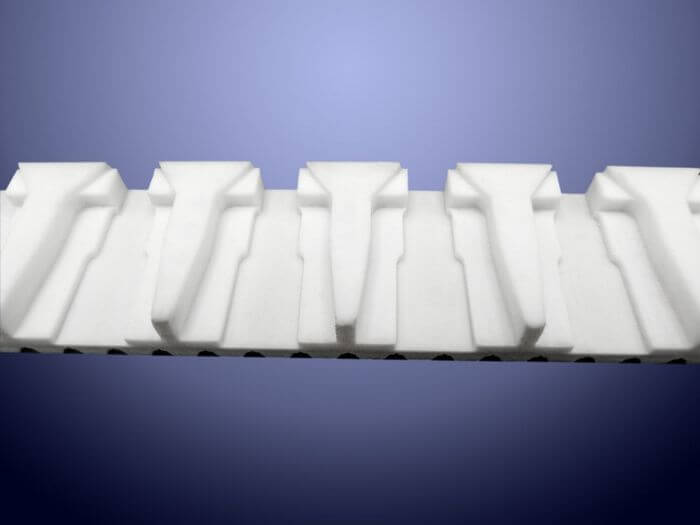

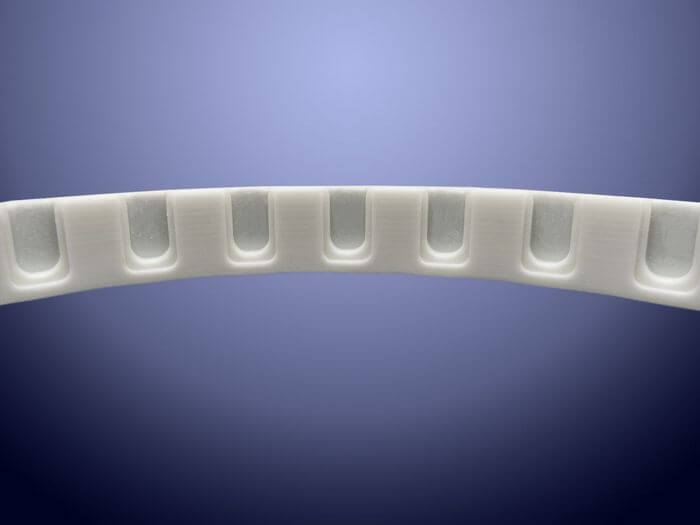

In the automatic machinery sector, certain applications require more grip than what the belt coating alone can provide. In such cases, the timing belt can be machined to function as a suction (vacuum) system.

Specifically, by creating a channel along the toothed side and adding perforations and corresponding slots on the coated back of the belt, suction can be applied to the product through the use of a vacuum pump, ensuring secure and precise transport.