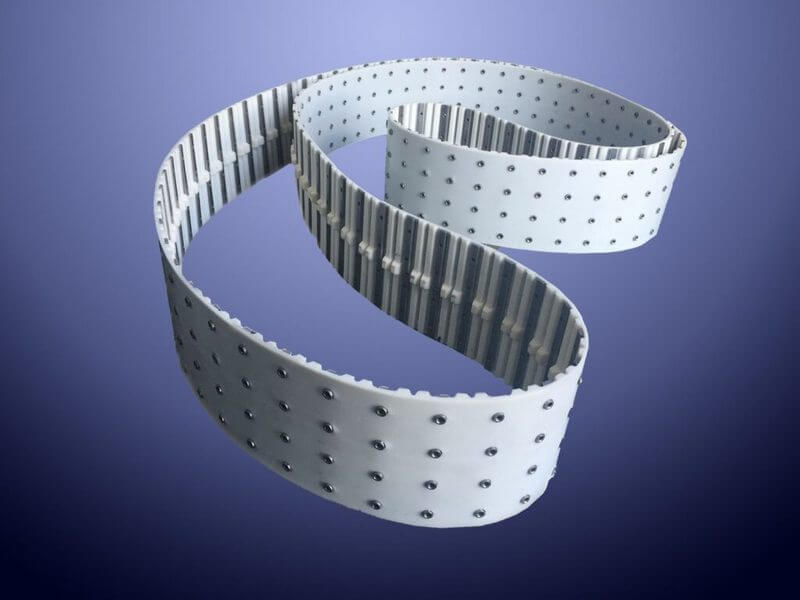

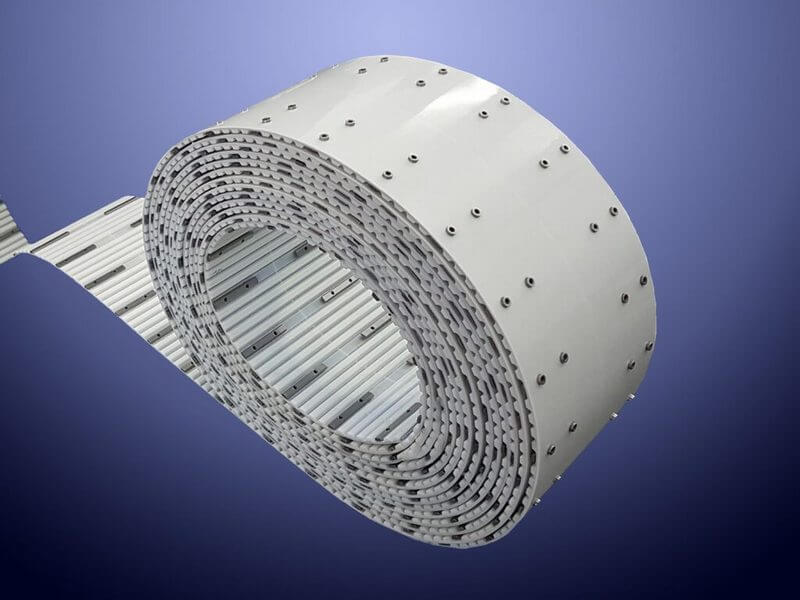

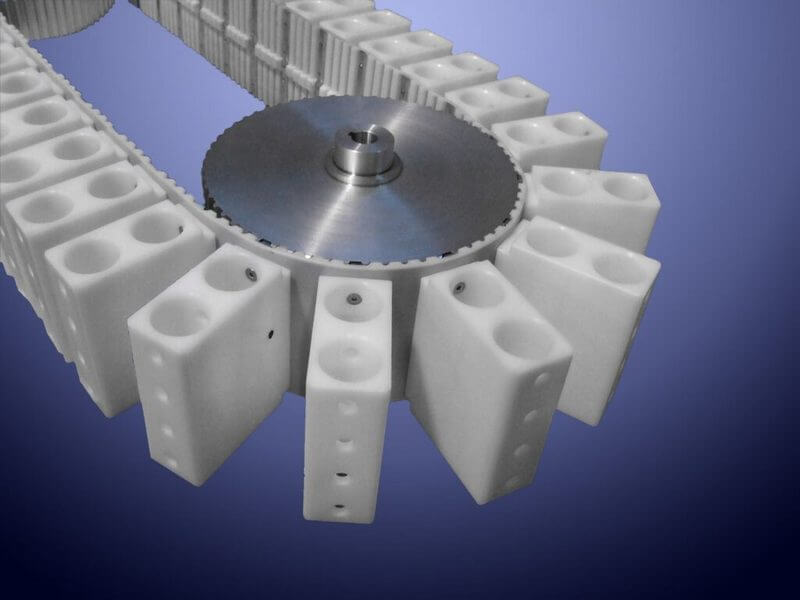

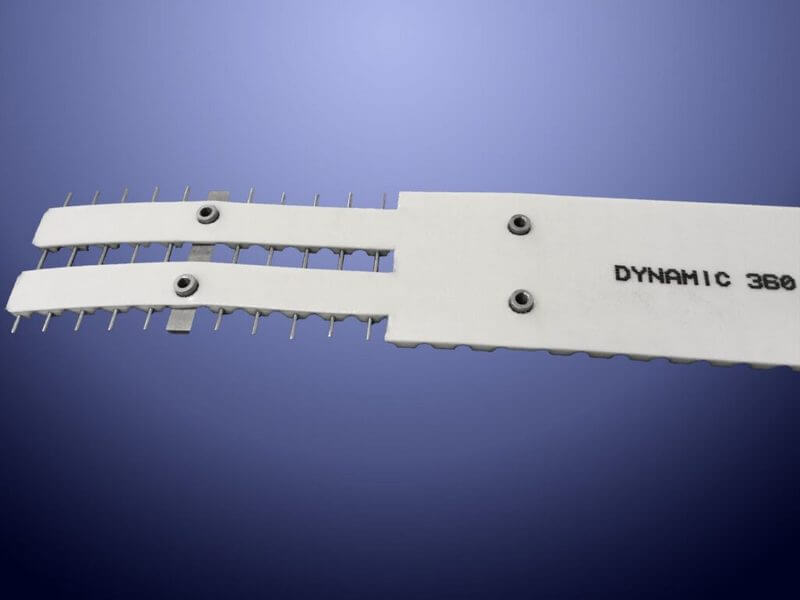

In recent years, timing belts equipped with mechanical false teeth and dedicated attachments have emerged as the preferred solution for synchronous product transport in a wide range of industrial applications. Their success lies in the ability to combine precise motion control with high adaptability to specific handling and positioning needs.

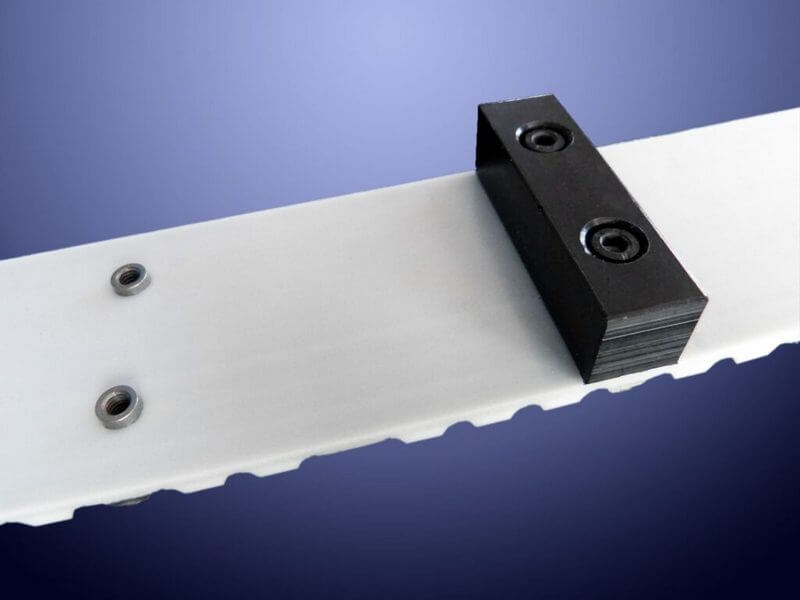

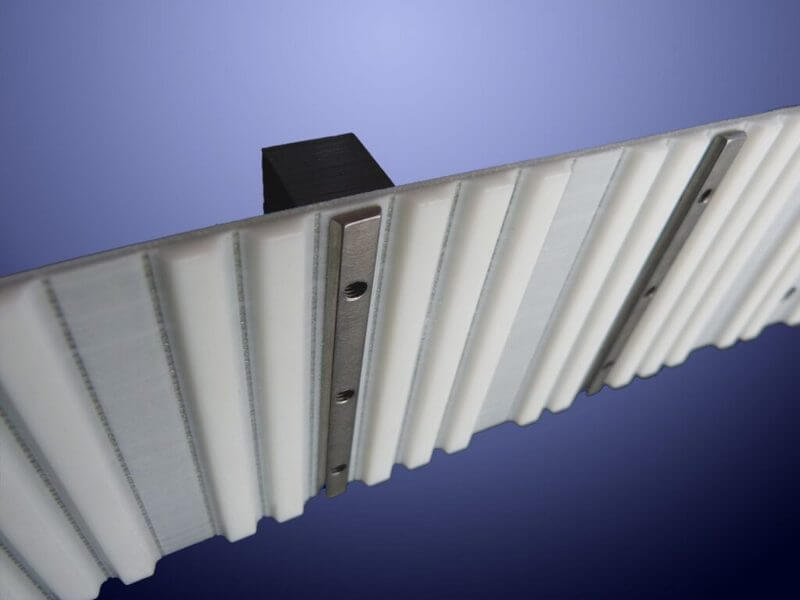

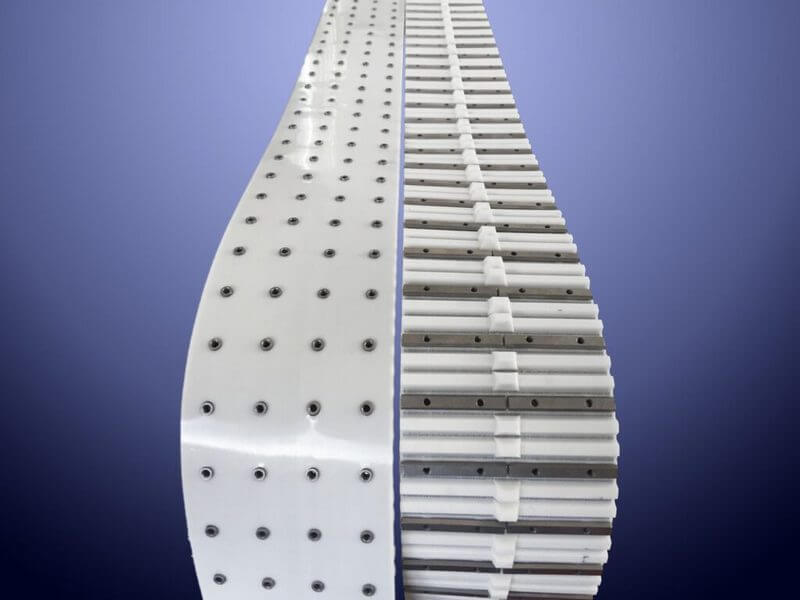

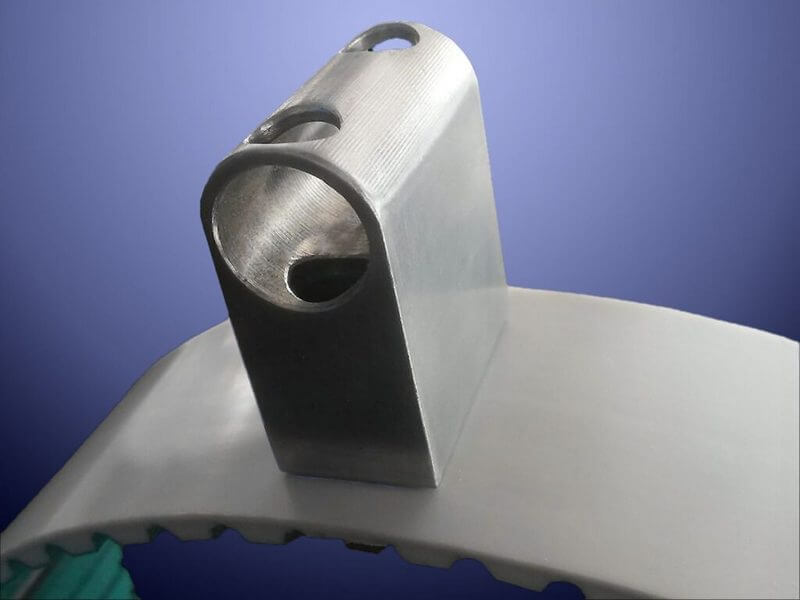

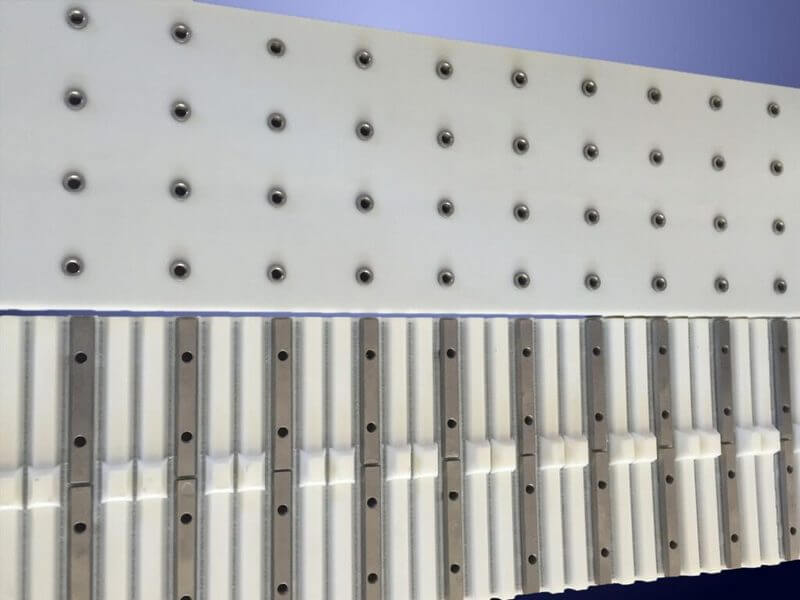

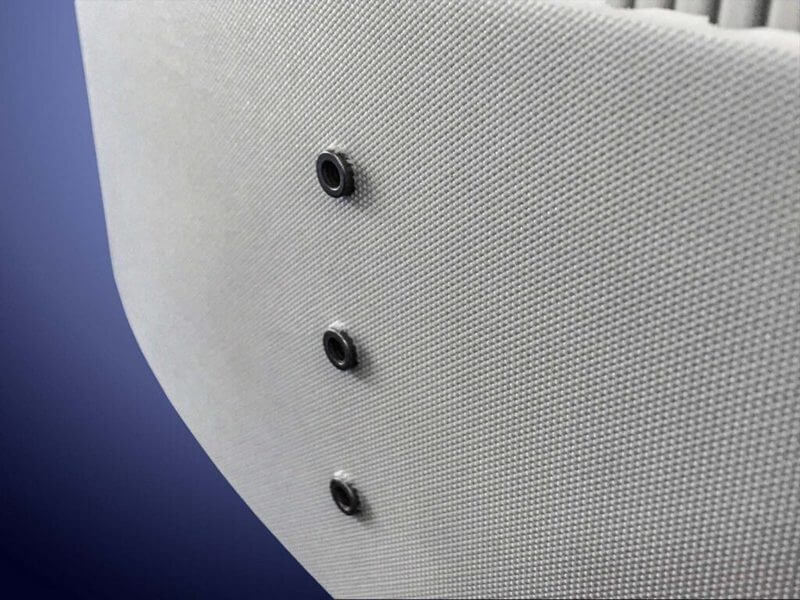

By replacing the standard molded teeth of the timing belt with threaded stainless steel inserts, manufacturers can securely fasten components, fixtures, or custom devices directly onto the back of the belt.

One of the key advantages of this system is the flexibility in the placement of the fastening bushes. These inserts can be positioned at custom intervals along the belt, allowing users to define the distance between attachments based on the layout and rhythm of their processes. This modular and versatile design makes the system ideal for use in automated machinery, packaging lines, and other environments where precision, reliability, and customization are essential.