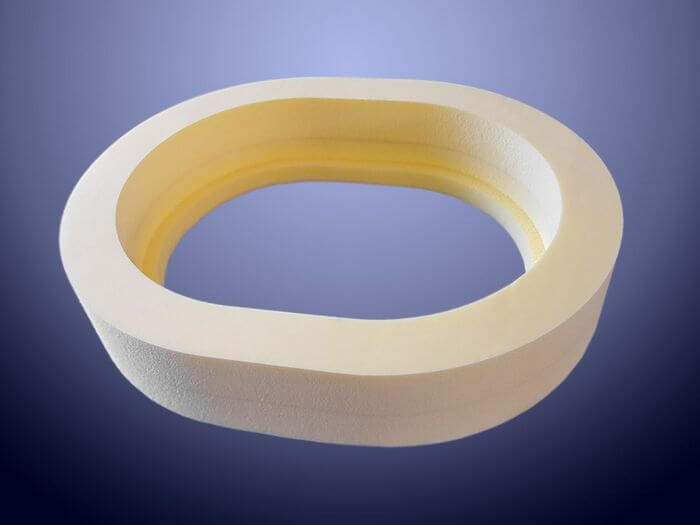

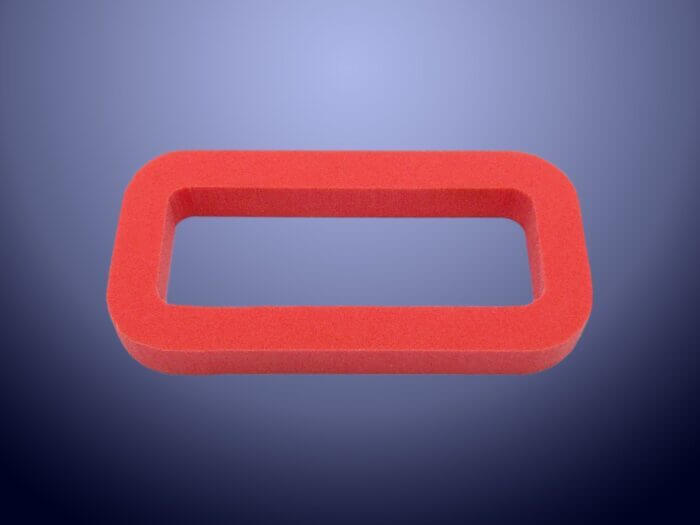

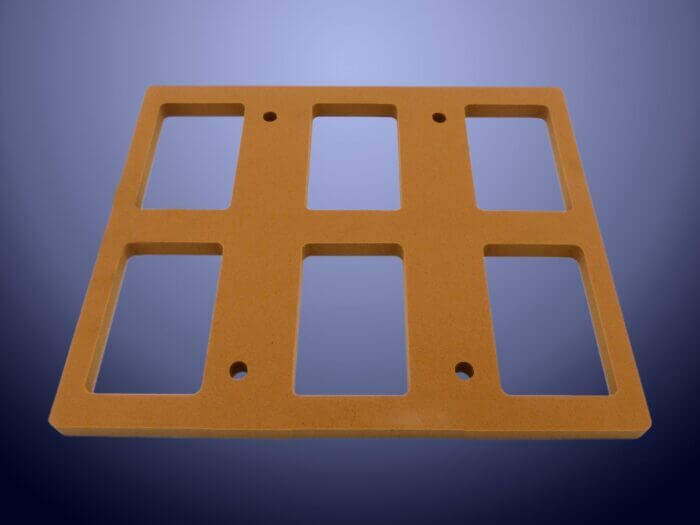

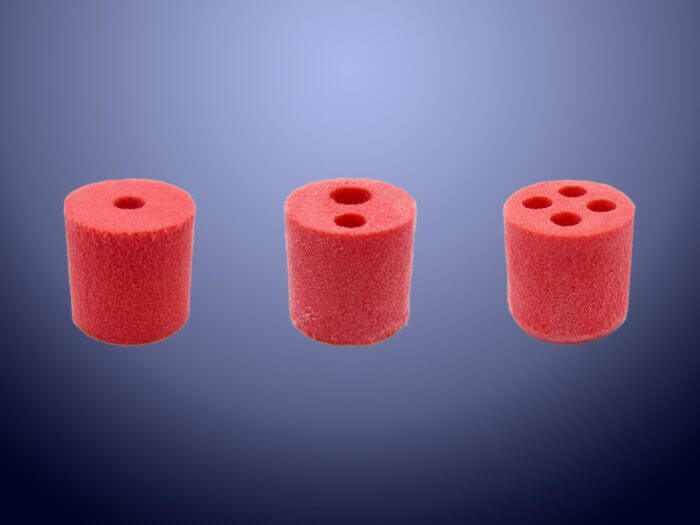

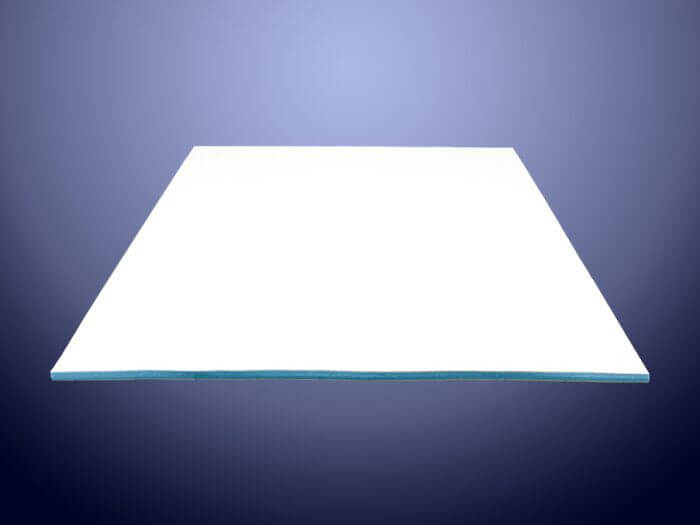

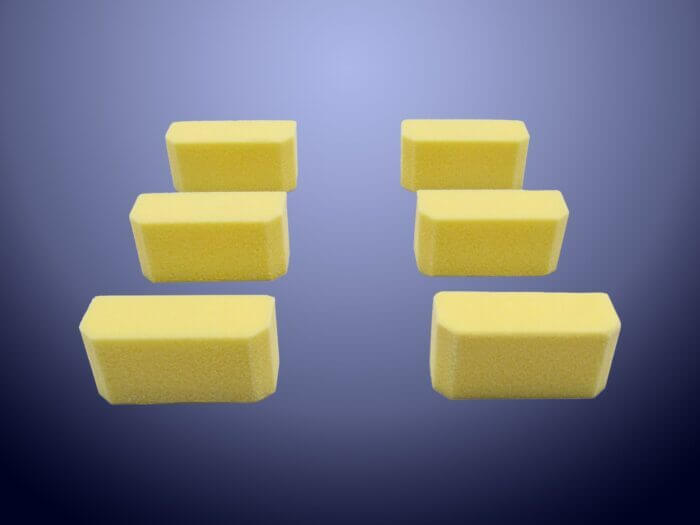

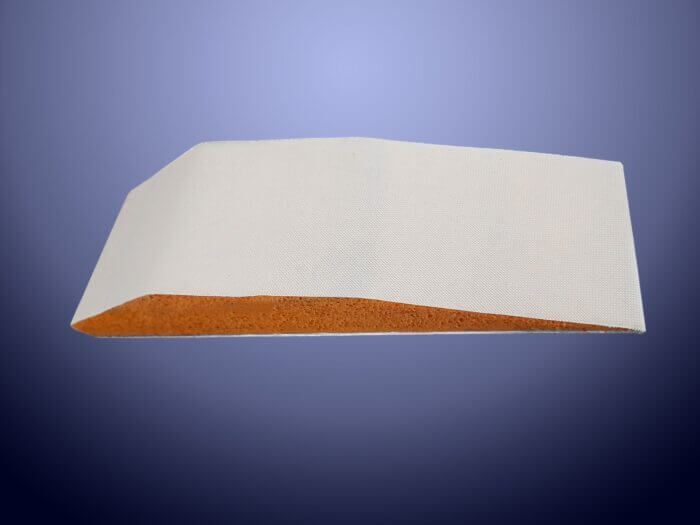

The foam coatings we frequently apply to timing belts have enabled us to develop a variety of components tailored for use in the automatic machinery sector. These include product blocking supports and pushers used along conveyor lines. Thanks to their flexibility, these components can adapt precisely to the shape of the product without causing any damage.

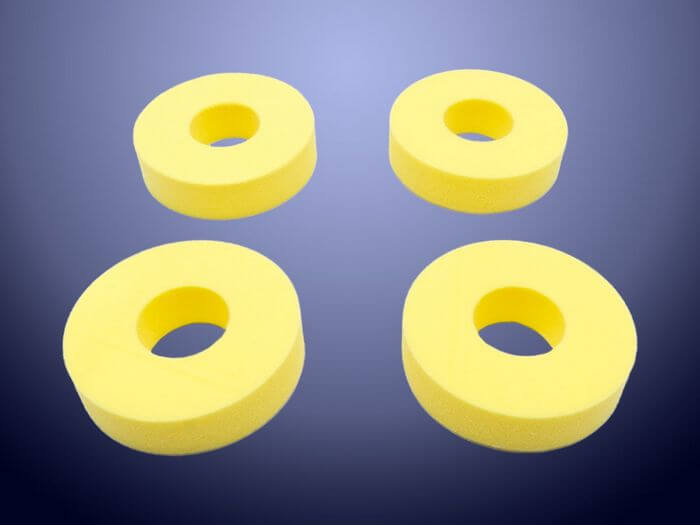

The materials we most often choose for these solutions are polyurethane foams, particularly Sylomer, which is available in a wide range of densities, colours, and thicknesses to ensure optimal performance for each specific application.

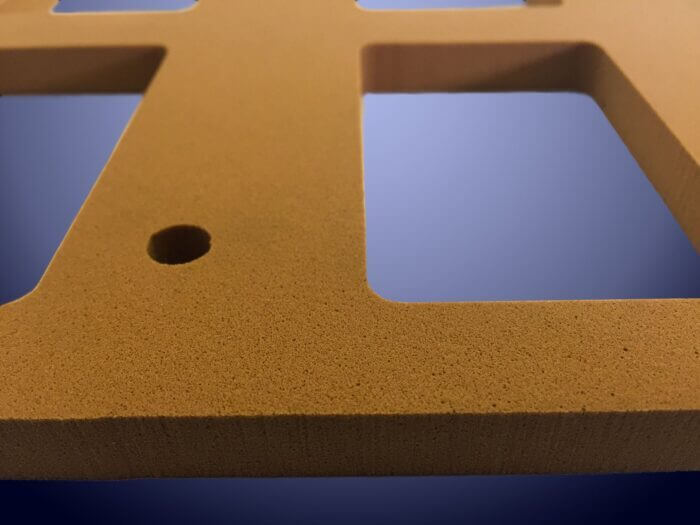

Machining of Foams

Our commitment to achieving flawless foam machining has driven us to invest in advanced technologies that enable us to design components rapidly and, most importantly, manufacture them to extremely high-quality standards.

A state-of-the-art milling machine, equipped with a dedicated set of tools, allows us to process all types of foam. Thanks to its granite base and high-speed spindle (40,000 rpm), we are able to machine even low-density materials like yellow Sylomer (150 kg/m³) with maximum precision.