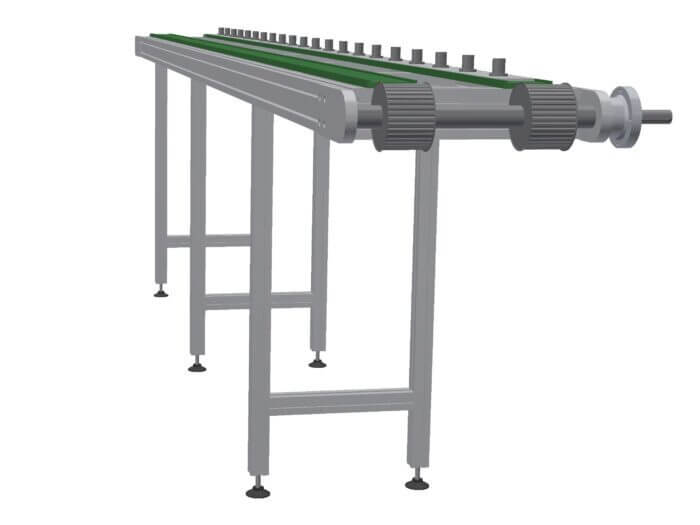

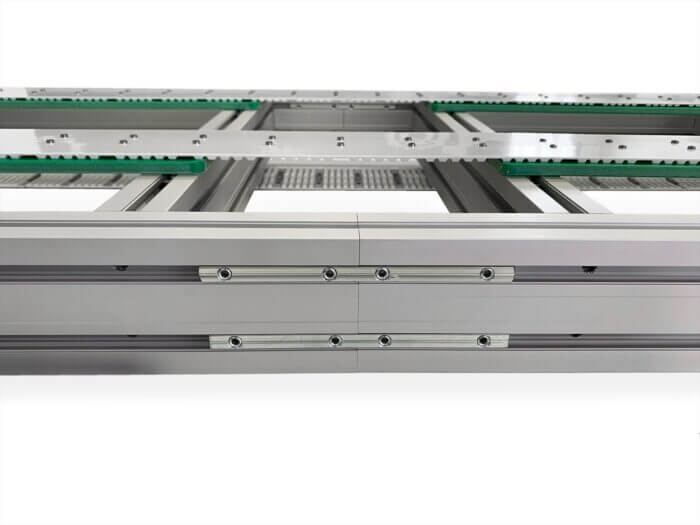

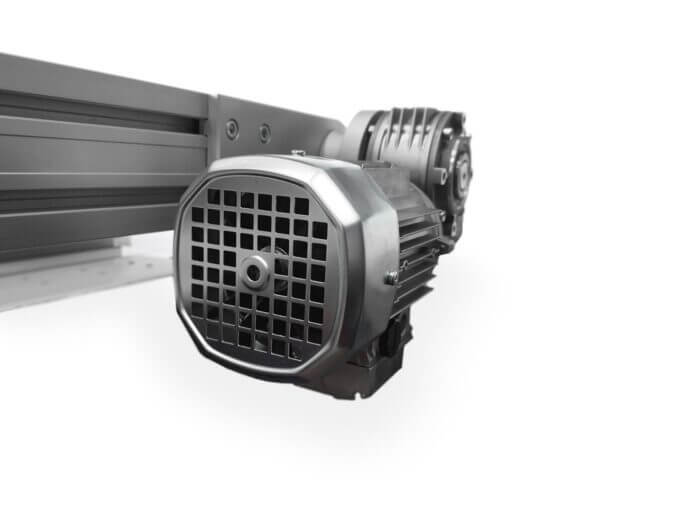

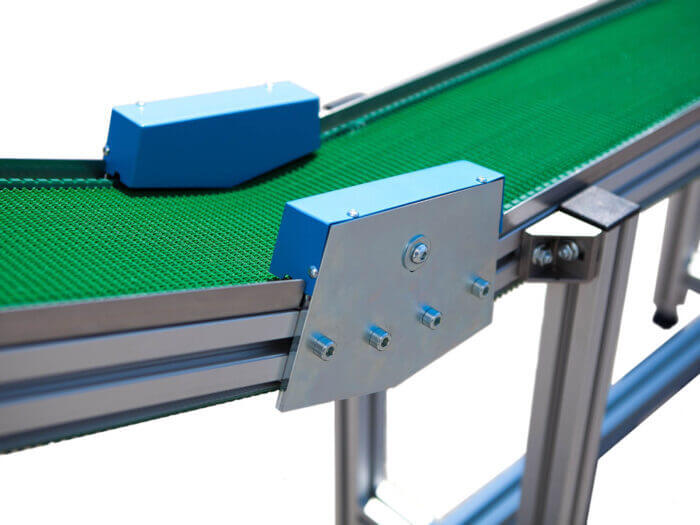

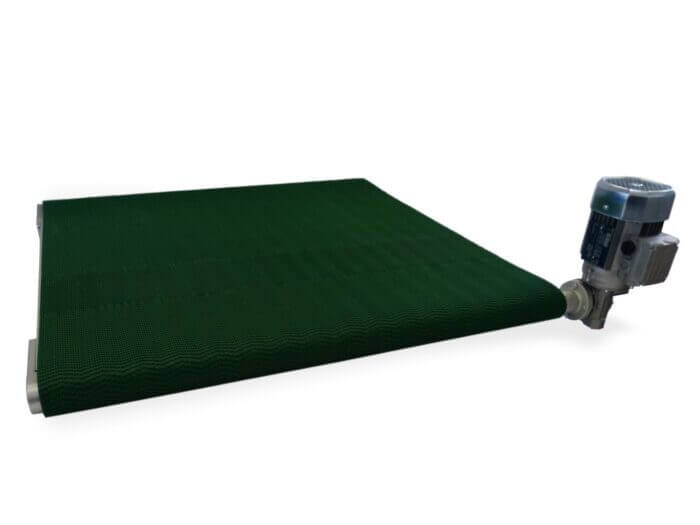

Our belt conveyors, built on a modular aluminium profile structure, are pre-assembled transport systems designed to accommodate both timing belts and smooth belts. These systems stand out for their simplicity, flexibility, and reliability, and can be easily configured to meet a wide range of application-specific needs thanks to the many available setup options.

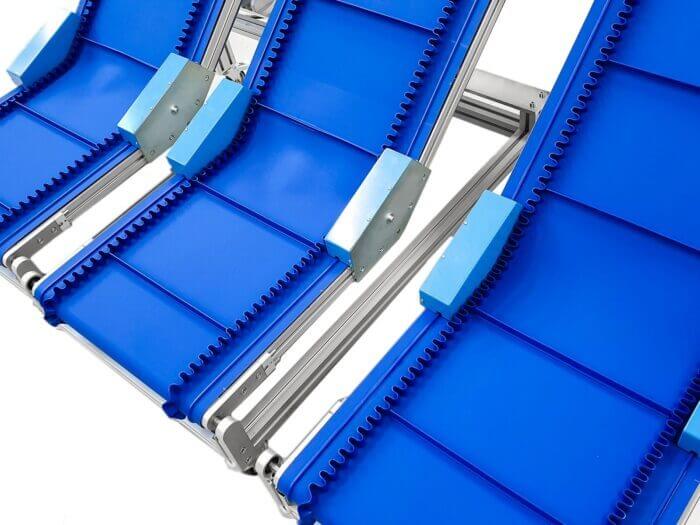

Synchronous Toothed Belt Conveyors

Our expertise with timing belts has enabled us to develop conveyor systems that offer significantly higher positioning precision compared to traditional smooth belt conveyors.

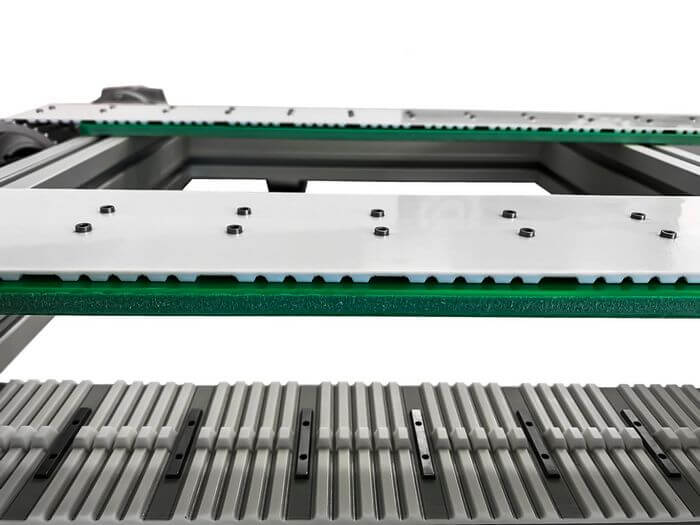

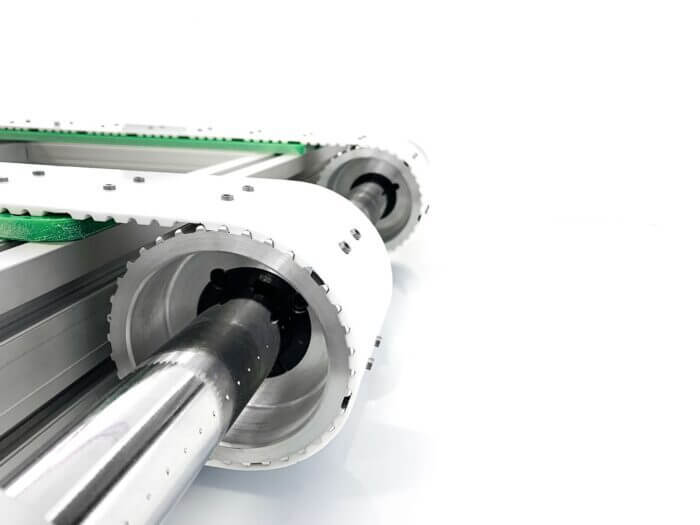

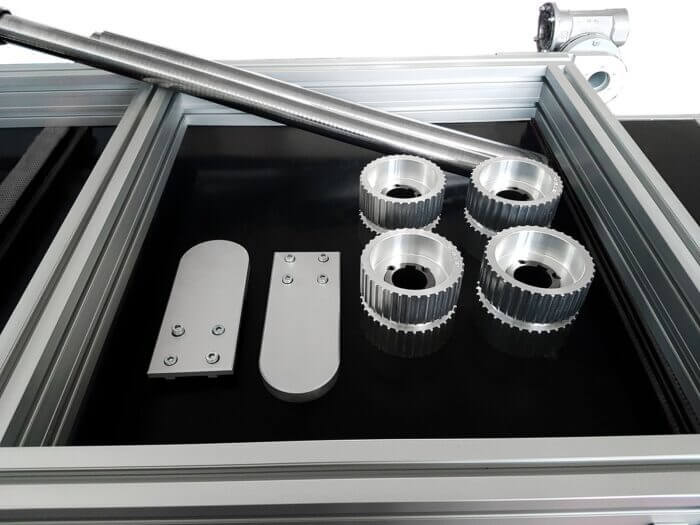

All timing belt types featured in the dedicated section of our website can be integrated into these systems. Using CAD design, we can tailor each conveyor to meet your specific needs. Thanks to the adjustable polyzene guide profiles and pulleys with conical bushings, the system offers great versatility, allowing easy adjustments to the width, position, and spacing of the timing belts.