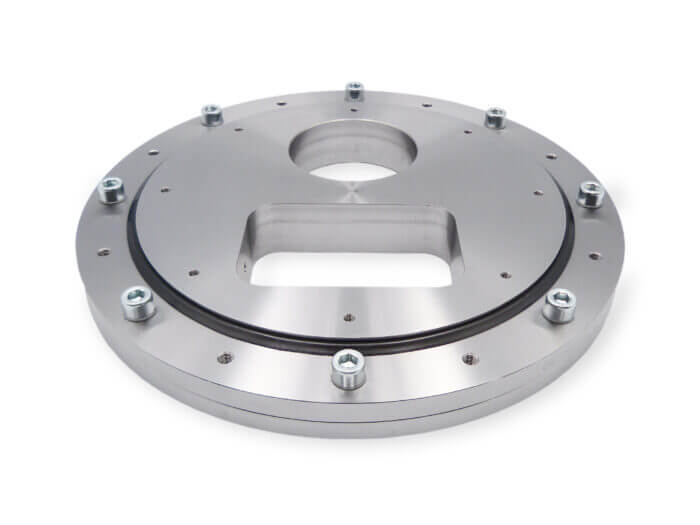

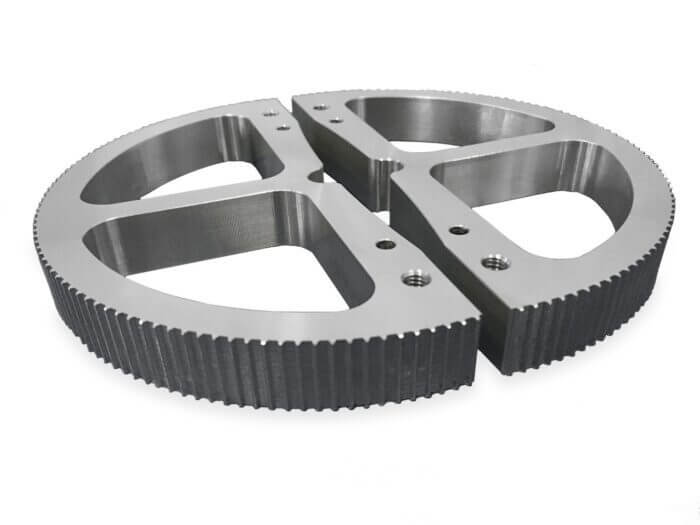

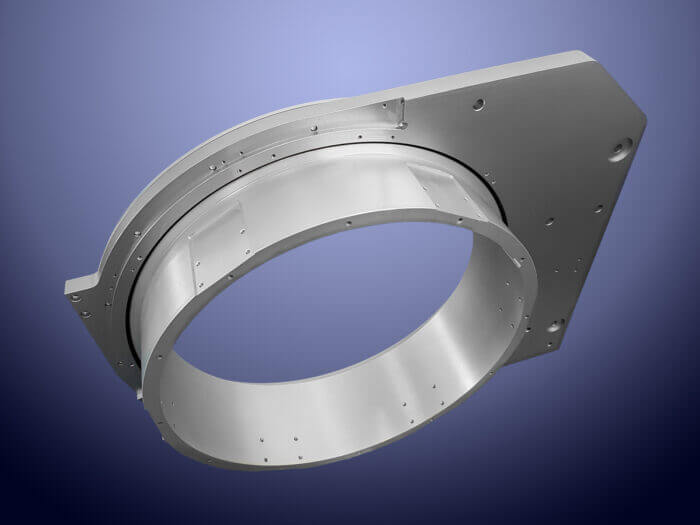

Our custom-made bearings and slewing rings are highly versatile rotational systems, as their external geometry is fully customizable to suit the specific application, allowing for the use of a wide variety of materials. These systems are capable of handling both axial and radial loads, reaching speeds of up to 10 m/s. Additionally, the preload applied to the bearing ensures a high level of rigidity, making them ideal for precision applications where stability and performance are critical.

Bearing elements integration

We offer a complete service that covers every phase — from the sizing and integration of the bearing elements to the full manufacturing of components according to customer drawings. Thanks to the advanced technology we use, we’re able to design the bearing geometry entirely in-house and provide a 3D model of the component, allowing the customer to verify its perfect compatibility with their project before production begins.